Stable 2022 Starshine Drive: Give full play to its own value and empower the textile industry

- Categories:Company News

- Author:

- Origin:

- Time of issue:2022-03-09

- Views:

(Summary description)As we all know, the textile industry has been developing vigorously. From the manual weaving in the past to the fully automated weaving, the production efficiency of the textile industry has been greatly improved with the help of machinery. The requirements for fabrics are getting higher and higher, and the previous textile machinery is also facing the crisis of being eliminated. Then, how to improve the precision of textiles and the density of textile fabrics, which requires the precision of textile machinery to be improved.

Stable 2022 Starshine Drive: Give full play to its own value and empower the textile industry

(Summary description)As we all know, the textile industry has been developing vigorously. From the manual weaving in the past to the fully automated weaving, the production efficiency of the textile industry has been greatly improved with the help of machinery. The requirements for fabrics are getting higher and higher, and the previous textile machinery is also facing the crisis of being eliminated. Then, how to improve the precision of textiles and the density of textile fabrics, which requires the precision of textile machinery to be improved.

- Categories:Company News

- Author:

- Origin:

- Time of issue:2022-03-09 15:11

- Views:

As we all know, the textile industry has been developing vigorously. From the manual weaving in the past to the fully automated weaving, the production efficiency of the textile industry has been greatly improved with the help of machinery. The requirements for fabrics are getting higher and higher, and the previous textile machinery is also facing the crisis of being eliminated. Then, how to improve the precision of textiles and the density of textile fabrics, which requires the precision of textile machinery to be improved.

The previous textile machinery used common gear reducers as the power source, with the advantages of low cost, high efficiency and simple operation. But at the same time, the disadvantages are also obvious, that is, the controllability is low, the precision is low, and the motor speed will change slightly under the influence of the voltage and current, resulting in a change in the output speed. In addition, the accuracy of the output speed of the ordinary reducer is not high. If the ordinary gear reducer is used as the power source to make high-end textile fabrics, the produced fabrics are very likely to be uneven, and there are problems such as large line spacing in some places. . At this time, it is necessary to use a high-precision reducer and motor as a power source. Next, I will introduce the starlight transmission reducer in textile mercerizing machine equipment, textile dyeing vat equipment, textile setting machine equipment, washing machine and other equipment. usage.

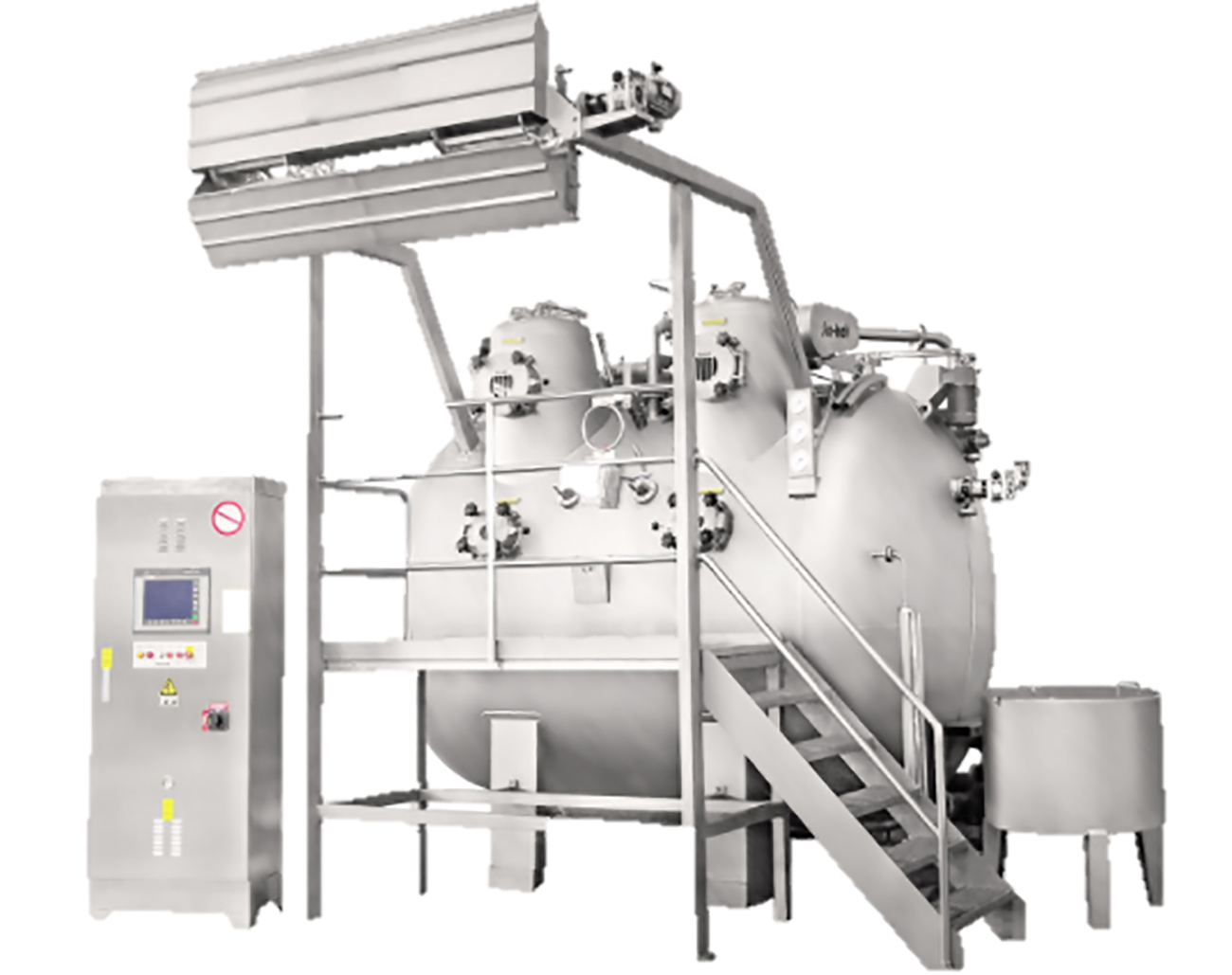

1. Reducer for dye vat drive

Product application: It is widely used in the corresponding institutions such as hair removal, swaying, mopping and so on in the textile dyeing vat equipment.

Product series: K, S, RV

Input power: 0.12-4 Kw

Reduction ratio: 5-800

Technical Features:

1. Compact size: the input and output shafts are arranged vertically, which is convenient for product installation and application.

2. Corrosion resistance: The surface is coated with strong corrosion-resistant paint to adapt to the appearance of acid and alkali solvents during dyeing.

3. Easy to install: shaft-mounted installation is available

4. Strong versatility: highly modular, serialized design, strong versatility and interchangeability

2. Reducer for driving of boiling, bleaching and washing machines

Product application: It is widely used in rubber-coated rollers, traction rollers, screen rollers, centering rollers, octagonal rollers, expanding rollers, cloth-beating rollers, automatic filters and other corresponding mechanisms in textile washing machines.

Product series: R, K, F, S

Input power: 0.12-7.5 Kw

Reduction ratio: 3.5-1600

Technical Features:

1. Low energy consumption: high-efficiency reducer and high-efficiency energy-saving motor, low operating cost.

2. Corrosion resistance: The surface is coated with strong corrosion-resistant paint to adapt to the influence of acid and alkali solvents during cooking and bleaching processes.

3. Wide speed regulation: It can be equipped with a wide base frequency motor to meet the process speed requirements between different fabrics.

4. Lightweight: The geared motor with the same power is more compact in size and lighter in weight, which improves the service life of the roller.

5. Easy installation: Shaft-mounted installation type can be used.

6. Fast delivery: high-precision modular design, optimal spare parts inventory to meet customers' product delivery needs

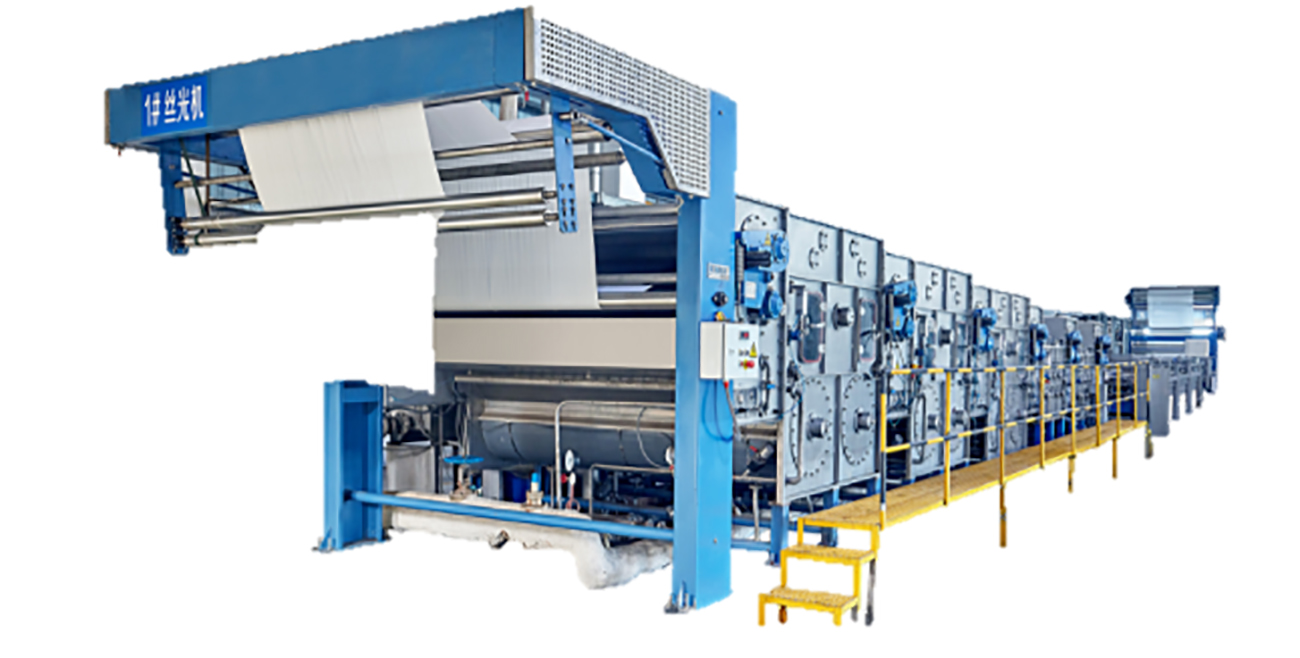

3. Reducer for mercerizing machine drive

Product application: widely used in textile mercerizing machine equipment covering rubber rolls, traction rolls, screen rolls, centering rolls, octagonal rolls, expanding rolls, driving rolls, automatic filters, and overfeeding, amplitude modulation motors and other corresponding mechanisms .

Product series: R, K, F, S

Input power: 0.12-7.5 Kw

Reduction ratio: 3.5-1600

Technical Features:

1. Low energy consumption: high-efficiency reducer and high-efficiency energy-saving motor, low operating cost.

2. High reliability: It can be equipped with a mechanical absolute encoder, with non-fault shutdown memory function.

3. Wide speed regulation: It can be equipped with a wide base frequency motor to meet the process speed requirements between different fabrics.

4. Lightweight: The geared motor with the same power is more compact in size and lighter in weight, which improves the service life of the roller.

5. Easy installation: Shaft-mounted installation type can be used.

6. Fast delivery: high-precision modular design, with optimal inventory to meet customer product delivery needs

4. Reducer for setting machine drive

Product application: Widely used in the centering, rolling, main chain, weft adjustment, amplitude modulation, width expansion, mopping, arranging, cloth feeding and other corresponding mechanisms in the textile setting machine equipment.

Product series: R, K, F, S

Input power: 0.12-15 Kw

Reduction ratio: 3.5-1000

Technical Features:

1. Low backlash: lower rotary backlash, through tension control, to ensure the synchronization of the rollers.

2. High reliability: It can be equipped with a mechanical absolute encoder, with non-fault shutdown memory function.

3. High temperature resistance: It can be adapted to the application of driving rollers with heat radiation.

4. Easy to install: shaft-mounted installation type

5. Fast delivery: high-precision modular design, with optimal inventory to meet customer product delivery needs

Scan the QR code to read on your phone

Hotline:+86-0757-66639854

Emai:sales@xgcd.cn

Add:No.10 Huijin industrial Park,Baini, Sanshui District, Foshan, Guangdong P.R. China

Copyright © 2022 Guangdong Starshine Drive Co.,Ltd All Rights 粤ICP备18154983号 www.300.cn SEO Tags

Chinese

Chinese English

English